Containerized Bitumen Emulsion Plant

Product Details:

- Product Type Bitumen Emulsion Plant

- Material Stainless Steel

- Voltage 220-280 Volt (v)

- Color Silver

- Click to View more

Containerized Bitumen Emulsion Plant Price And Quantity

- 100000.00 INR

- 1 Unit

Containerized Bitumen Emulsion Plant Product Specifications

- Silver

- 220-280 Volt (v)

- Bitumen Emulsion Plant

- Stainless Steel

Containerized Bitumen Emulsion Plant Trade Information

- Cash on Delivery (COD) Cash in Advance (CID) Cash Advance (CA)

- 1 Unit Per Day

- 1 Days

- Wooden

- Australia North America Eastern Europe Africa Central America Middle East South America Western Europe Asia

- All India

Product Description

Containerized Bitumen Emulsion Plant

Blessed and supported by the team of high skilled and talented personnel, our company is considered as one of the leading manufacturers and exporters of Containerized Bitumen Emulsion Plant. Some of the distinguished features that are loaded in our emulsion plant are long working life, high operational fluency and seamless performance. These find application in various industries for instance paper, plastic and agro chemical industry. Economically priced, Bitumen Emulsion Plant offered by our company is engineered under the astute guidance of quality controllers as per the industry predefined norms and standards.

BITUMEN EMULSION PLANT BATCH TYPE:

Large volumes of water bitumen emulsion are used in various constructional activities like road building, asphalt road surfacing and waterproofing applications and which result in cost savings and superior results.

Bitumen in molten form is mixed with water and emulsifier chemicals by means of a high shear, high speed in-line mixer to form a stable emulsion at room temperature. Bitumen and water are mixed in different rates depending upon application. Typically they are in the proportion 50:50 or 60:40. or different grades as Medium setting, Rapid setting, Slow setting etc.

A complete plant normally comprises three stages viz:

1.) Raw material( Bitumen, water, emulsifiers) storage, handling and transfer.

2.) Mixing, emulsifying and handling.

3.) Product storage

This unit comprises the second phase namely mixing, dissolving and transfers

This plant is a unitized arrangement with all elements and subassemblies mounted on a skid type base frame of a size that is conveniently transportable to site.

It typically comprises of the following:

1.) Water and Bitumen emulsion processing/ storage vessel

2.) Molten Bitumen holding vessel

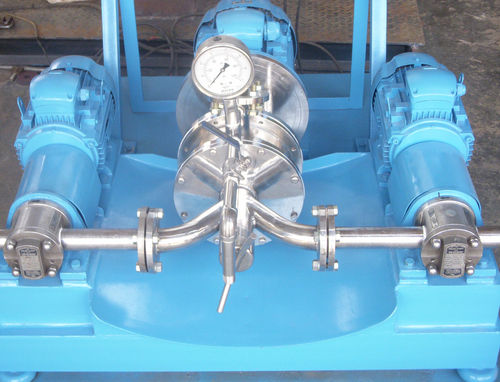

3.) High shear in-line mixer/emulsifier

4.) Molten Bitumen feed pump

5.) Auxiliaries like heaters, control panel, flushing and cleaning arrangements

The molten Bitumen vessel is insulated on the outside and has 2 nos immersion type heaters at its bottom end for maintaining the temperature at 140-160 C.

Motorized agitator assembly is mounted on top to keep the bitumen/emulsion stirred.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Bitumen Emulsion Plant' category

|

WAHAL PROCESS TECHNOLOGIES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |