Bitumen Emulsion Machine

Product Details:

- Product Type Emulsion Machine

- Material Stainless Steel

- Weight (kg) 1050 Kilograms (kg)

- Voltage 220 Volt (v)

- Color Sky Blue And Silver

- Click to View more

Bitumen Emulsion Machine Price And Quantity

- 1 Unit

- 100000 INR

Bitumen Emulsion Machine Product Specifications

- Emulsion Machine

- Stainless Steel

- 220 Volt (v)

- 1050 Kilograms (kg)

- Sky Blue And Silver

Bitumen Emulsion Machine Trade Information

- Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID)

- 1 Unit Per Day

- 1 Days

- Wooden box

- Middle East Central America Eastern Europe Africa South America Western Europe Australia Asia North America

- All India

Product Description

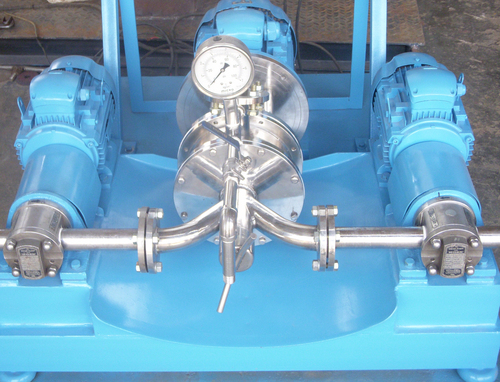

Bitumen Emulsion Machine

Relying on our wide experience and skilled workforce, we are considered to be the most reputed manufacturers and exporters of Bitumen Emulsion Machine. These machines find application in various constructional activities like road building, asphalt road surfacing and waterproofing applications. We make sure that these machines are manufactured as per requisite industrial norms and standards. Our offered assortment is widely appreciated for its robust construction, long service life and impeccable performance. We offer heavy duty Bitumen Emulsion Machine at market leading prices.

Further Details:

Large volumes of water bitumen emulsion are used in various constructional activities like road building, asphalt road surfacing and waterproofing applications and which result in cost savings and superior results.

The bitumen in molten form is mixed with water and emulsifier chemicals by means of a high shear, high speed in-line mixer to form a stable emulsion at room temperature. Bitumen and water are mixed in different rates depending upon application. Typically they are in the proportion 50:50 or 60:40. for diffrent grades as RS, MS, SS.

A complete plant normally comprises three stages viz:

1.) Raw material( Bitumen, water, emulsifiers) storage, handling and transfer.

2.) Mixing, emulsifying and handling.

3.) Product storage

This unit comprises the second phase namely mixing, dissolving and transfers

This plant is a unitized arrangement with all elements and subassemblies mounted on a skid type base frame of a size that is conveniently transportable to site.

It consists of the following:

Continuous batch type plant for the production of anionic as well as cationic emulsion of all grades. This is a semi batch type plant that gives output of up to thirty ton per hour. Plus, two tanks of 10 kl capacity are also installed alongside. Both these tanks are supplied feed from the acid tank, water tank, emulsifier tank, etc. Equipped with low & high level sensors, both these tanks are capable of being filled in around thirty minutes or less. Water is moved through a high capacity centrifugal pump. While on the other hand the chemicals & additives are dosed through dosing/metering pumps in the required quantity/proportion. The filled batch is now set to feed into the mixer/in-line homogenizer.

The tank T2 comes on line when the emptying process of tank T1 is complete. At this point, tank T1 is cut off. Simultaneously, it starts again to get filled in for the upcoming cycle. The dispersion/ homogenizer unit is our specially designed mixer. This high shear mixer in SS-304/316 construction has four stages and produces homogenized emulsion single pass. The water mix & molten bitumen are fed into the mixer through high quality VFD motor driven gear pumps. With the help of PLC controller, the mix ratio can also be adjusted as per the requirement. Moreover, each feed pump is equipped with in-line flow meter along with flow transmitter. Therefore, on line control of the needed proportions of the two components can be easily maintained.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Bitumen Emulsion Plant' category

|

WAHAL PROCESS TECHNOLOGIES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |