Inline Four stage homogenizer

100000.00 INR

Product Details:

- Type Four stage homogenizer

- Material Stainless Steel

- Automatic Grade Semi-Automatic

- Voltage 200-280 Volt (v)

- Weight 5500 Kilograms (kg)

- Click to View more

X

Inline Four stage homogenizer Price And Quantity

- 100000.00 INR

- 1 Unit

Inline Four stage homogenizer Product Specifications

- Stainless Steel

- Semi-Automatic

- Four stage homogenizer

- 200-280 Volt (v)

- 5500 Kilograms (kg)

Inline Four stage homogenizer Trade Information

- Cash on Delivery (COD) Cash in Advance (CID) Cash Advance (CA)

- 1 Unit Per Day

- 1 Days

- Wooden Box

- Western Europe Australia North America South America Eastern Europe Middle East Africa Central America Asia

- All India

Product Description

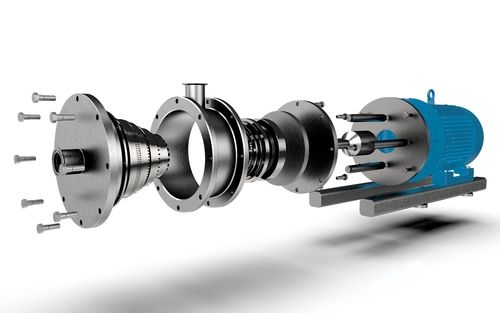

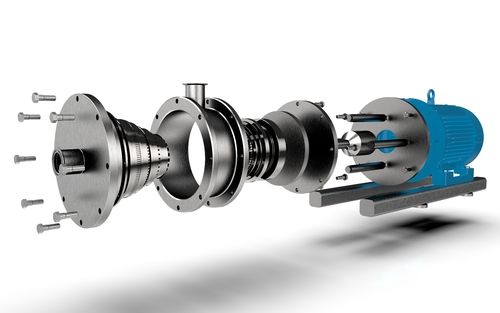

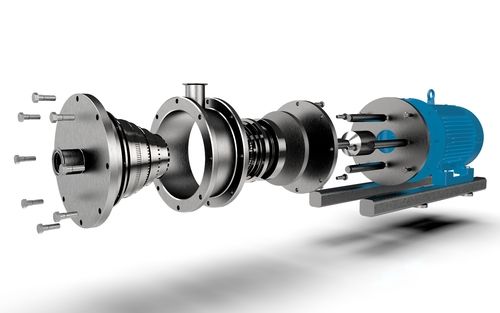

Manufactures a range of homogenizers specially design to work on the principle of shear force. Shear force is the force acting due to the shearing produced in between a rotating and a stationary parts. The same principle in being used wherein the homogenizer comprises of a rotatory part called the rotor and a stationary parts called the Stator. There are a various combinations of precision engineered rotor-stator assembly specific to the application of use. And one can have a range of the rotor-stator assembly to perform various homogenization applications.The homogenizers can be sub-categorized into the following:

- Continuous Homogenizers wiz single, two and four stage inline homogenizer

- Batch Homogenizers wiz intank and bottom mounted batch homogenizers

1.1.Single Stage Inline Homogenizer:

Single Stage Inline homogenizer comprises of a single set of a rotor stator assembly having various configurations of stator heads based upon the application. The single stage homogenizers have the following specs:

1.2.Two Stage Inline Homogenizer:

Two Stage Inline homogenizer comprises of two sets of a rotor stator assembly having various configurations of rotor-stator heads based upon the application. The two stage homogenizers have the following specs:

1.3.Four Stage Inline Homogenizer:

Four Stage Inline homogenizer comprises of four sets of a rotor stator assembly having various configurations of rotor-stator heads based upon the application. The four stage homogenizers have the following specs:

Binary entrance for merging partial flows

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Homogenizer' category

|

WAHAL PROCESS TECHNOLOGIES PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |